1. After the liquid filling machine is used, the fixed screws should be removed when the piston is removed during maintenance to avoid affecting the entire cleaning process. Use clean water to flush away the residues in the piston and pipeline in time to keep them clean, so as to ensure the filling quality for the next use.

2. Because the cylinder has been lubricated before leaving the factory, please do not open or add extra lubricating oil to ensure that the surface of the filling machine is clean and hygienic. Power off when it is not working.

3. Check the fixing condition of the various parts of the liquid filling machine when starting up, keep the structure compact and the parts fixed, and extend the service life, otherwise the service life will be shortened.

4. If you find that the machine is abnormal when it is working, you should immediately cut off the power supply and correct the abnormality before continuing to use it.

5. When using in winter, if the temperature is below 0°C, hot water must be used to melt the icy matter in the quantitative pump and the pipeline. If it does not melt, the cylinder may be broken and cannot be used, or the machine cannot be started.

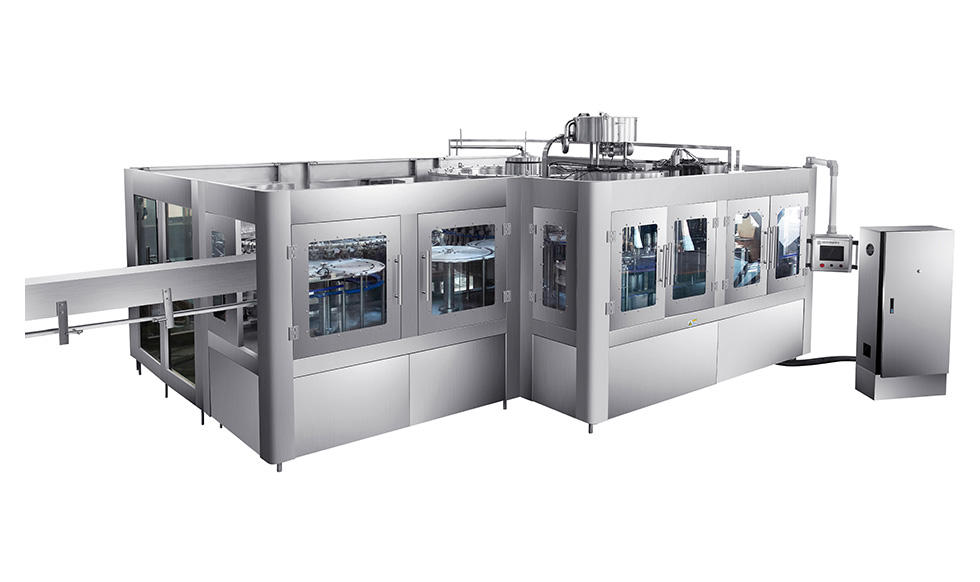

Master Packing Co.,Ltd was founded in 1997, is a professional China Filling Machines manufacturers and Filling Machines factory. Because of Advanced CNC machinery, 5 axis drilling machine, Lathe, a group of more than 15 years experienced engineers, Master brand Packing machine now exported more than 87 countries and district.Master Packing focus on Injection mold machine, PET/PP bottle blowing machine, PET/Glass/Can filling line and custom Filling Machines for sale, Also Master Packing supply the labeling machine and molds. Master packing design and manufacturing the simplest machine, let customer has ability to run and operate the machine in short time, Meanwhile, Master packing is strict with the quality control, Supply customer with stable and long life machine.

English

English España

España