Due to its good ductility, easy molding, and good stability, PET has a wide range of applications. In addition to food plastic bottles, plastic cosmetic bottles, plastic medicine bottles, etc. It is also used in film sheet series, such as daily shopping bags; as well as film film, photosensitive film and other substrates; electrical components, auto parts, mechanical equipment and other fields are also widely used.

The molding process of PET plastic can be injection molding, extrusion, blow molding, coating, bonding, machining, electroplating, vacuum metallization, printing

PET plastic is the abbreviation of English, referred to as PET or PETP. The natural color of PET material is transparent, has good formability, and is relatively easy to produce and process. PET is resistant to weak acids, has good stability under normal conditions, has low corrosion resistance and low water absorption, and also has good electrical insulation. However, PET is not resistant to high temperatures, even if it is a special high temperature resistant PET, the higher temperature it can withstand is only about 83 degrees. Therefore, PET products cannot be boiled, otherwise they will be deformed and harmful substances will be precipitated.

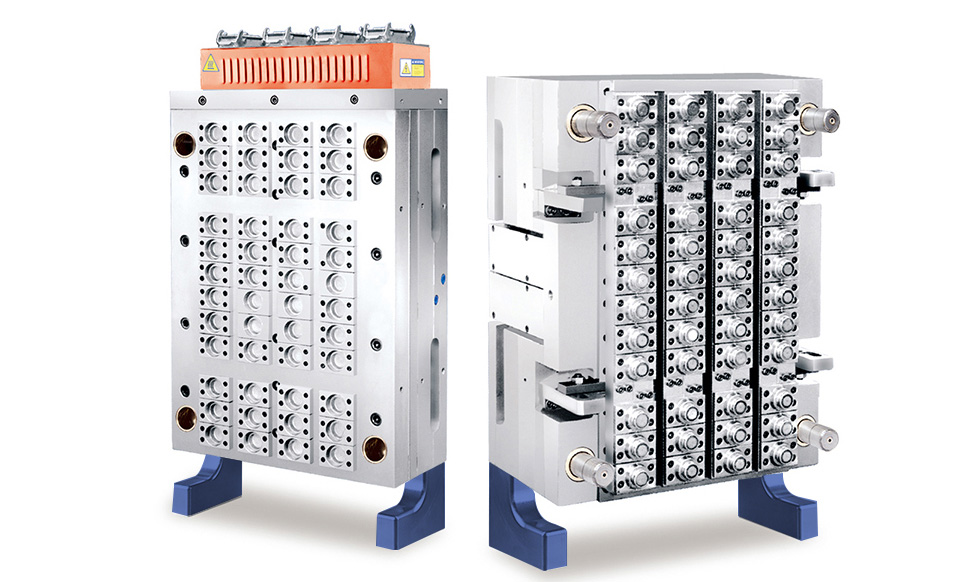

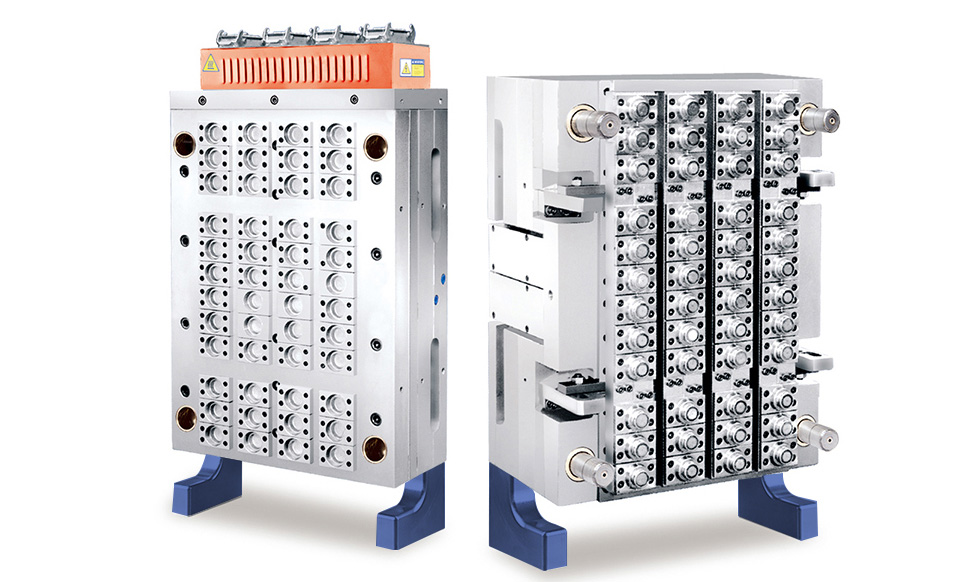

48 Cavity PE Injection Cap Mold

Cap Mold Feature - Petblowingmachine

1.Interchangeable insert is available for easy maintenance and long mould life.

2.Each cavity and core have independent cooling system, shortening production cycle time and getting high production efficiency.

3.Export standard mould; we are honest on steel material and mould components.

4.Testing mould and cap before shipping to your country, and we supply spare parts for you in one year if damage.

5.Tooling Machine is from Japan, which is good at precision machining to ensure low eccentricity.

English

English España

España