The working principle is different

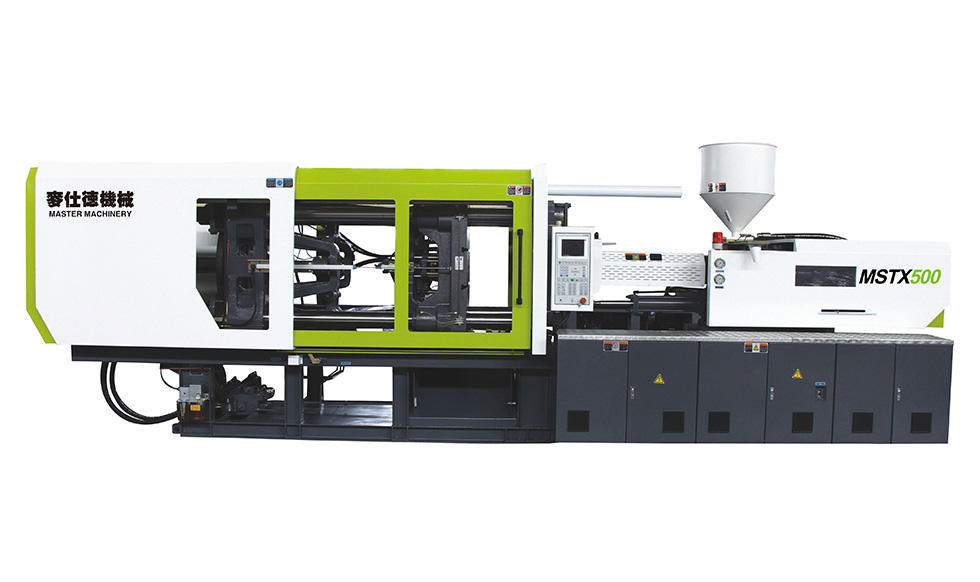

The working principle of the injection molding machine is similar to the syringe used for injection. It uses the thrust of the screw (or plunger) to inject the plasticized plastic in the molten state (that is, the viscous fluid state) into the closed mold cavity. The process of obtaining products after curing and shaping.

Injection molding is a cyclic process, each cycle mainly includes: quantitative feeding-melting plasticization-pressure injection-mold filling and cooling-mold opening and taking parts. After taking out the plastic part, the mold is closed again for the next cycle.

2. Extruder

A single screw is generally divided into three sections in effective length. The effective length of the three sections is determined according to the diameter, pitch and depth of the screw, which are generally divided into one third of each.

The last thread of the material port is called the conveying section: the material must not be plasticized here, but it must be preheated and compacted. In the past, the old extrusion theory believed that the material here is loose, and later proved that the material here is actually The solid plug means that the material here is a solid like a plug after being squeezed, so as long as the conveying task is completed, it is its function.

English

English España

España